No products in the cart.

Close

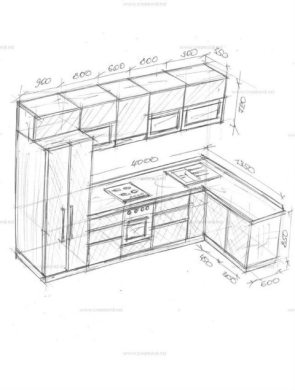

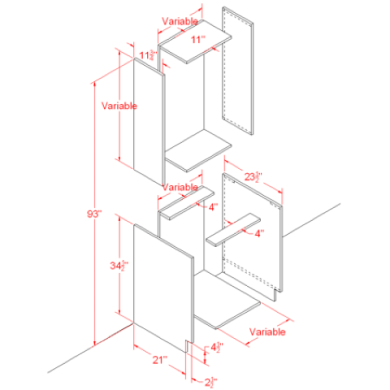

At TRADE FOR ALL thanks to the valuable help of a state-of-the-art design program we can provide you with fast and optimal solutions for the construction of kitchen furniture, wardrobe and other wood furniture. The design department is thus able to assist in offers and orders concerning:

Cuts are optimised and production machines are programmed to achieve the shortest possible customer service. At the same time, our qualified staff is always willing to solve any questions, assess needs and focus on any technical and manufacturing details that require special attention. The ultimate goal of all is the best possible response to the customer's requirements.

At TRADE FOR ALL we give the customer the possibility to submit his order as he wishes and it is easier for him by choosing one of the following written options:

1.Slicing-Welding (and partial drilling) of panels

2.Slicing-Welding-Drilling panels

At the disposal of our customers, however, there are the following indicative order forms per case, which aim to facilitate their order submission:

The ALTAS 100 is a shredder that has an automatic panel loader, is online connected to our design program and has a sticker printer where the customer's and the piece's details are printed. These features make it a valuable tool in achieving optimum productivity.

The H80 is a multi-function CNC-Nesting machine including mathematically precise cutting and surface cut optimization. Like the shredder, this machine has an automatic loader, a sticker printer and is linked to the design program which makes it one of the most important machines in the production process. The difference between this machine and the slicer is that it can make vertical holes on surfaces (discussed below in the subsection 'Perforation').

The H80 is a CNC-Nesting machine that, in addition to cutting (discussed in the subsection "Cutting"), also serves in vertical surface treatments. Some of these are hinge, cavity, screw, ferrule, scaffolding and even kinematics drilling. It is online connected to the design program and executes the commands it gives. When the cutting and punching processes are completed, a self-adhesive label is printed with the customer's details and the dimensions, welding points and horizontal punching points of each individual piece.

The CREATOR is a machine that serves for horizontal drilling on surfaces, after they have been passed by the cutting, welding or CNC-Nesting. It is also connected to the design department and has a Laser Scanner that reads the sticker with the horizontal drilling barcode of the part in question in order to maximize productivity and avoid errors.

In TRADE FOR ALL the correctly packed order is the final but very important stage of the execution of an order. The completeness and quality of the order is checked first and then it is evaluated whether it needs to be shipped on a pallet or not. Orders destined for agency delivery are wrapped with cardboard, while for in-house deliveries they are wrapped with plain transparent onwine. The H80 is a multi-function CNC-Nesting machine including mathematically accurate slicing and surface cut optimization. Like the shredder, this machine has an automatic loader, a sticker printer and is linked to the design program which makes it one of the most important machines in the production process. The difference between this machine and the slicer is that it can make vertical holes on surfaces (discussed below in the subsection 'Perforation').

After the completion of the order and if the delivery is to a location outside the headquarters of TRADE FOR ALL, it will be sent to the agency that the customer will indicate to us. At this stage, the company draws the attention of the carrier to take care of the products as they are fragile, in order to avoid as effectively as possible any shocks during transport. For in-house orders, delivery of orders is made at the company's premises.The H80 is a multi-function CNC-Nesting machine including mathematically accurate slicing and surface cut optimization. Like the shredder, this machine has an automatic loader, a sticker printer and is linked to the design program which makes it one of the most important machines in the production process. The difference between this machine and the slicer is that it can make vertical holes on surfaces (discussed below in the subsection 'Perforation').

Our company is ready to respond promptly and consistently to the requests of its customers. We believe that the customer is the driving force that makes us evolve and become better every day.

© 2022 - TRADE FOR ALL. CREATED BY Freespirits.gr